When we talk about modern industrial identification, product traceability, and long-lasting engravings, laser marking is one of the most advanced solutions available today. It’s not just a tech buzzword—it’s a method that has transformed how manufacturers, engineers, and even small businesses label parts, customize products, and ensure compliance in high-standard industries.

Unlike traditional methods such as ink printing, mechanical engraving, or chemical etching, laser marking relies on a focused beam of light to create permanent marks on a surface without physical contact. This results in greater precision, higher durability, and zero need for consumables like ink or solvents. If you’re looking for a clean, accurate, and eco-friendly method of marking materials—from metals to plastics—laser marking is often the first recommendation from experts.

In this article, I’ll break down how laser marking works, why industries depend on it, where it stands compared to other marking methods, and how related technologies like laser paint removal fit into the bigger picture of surface processing.

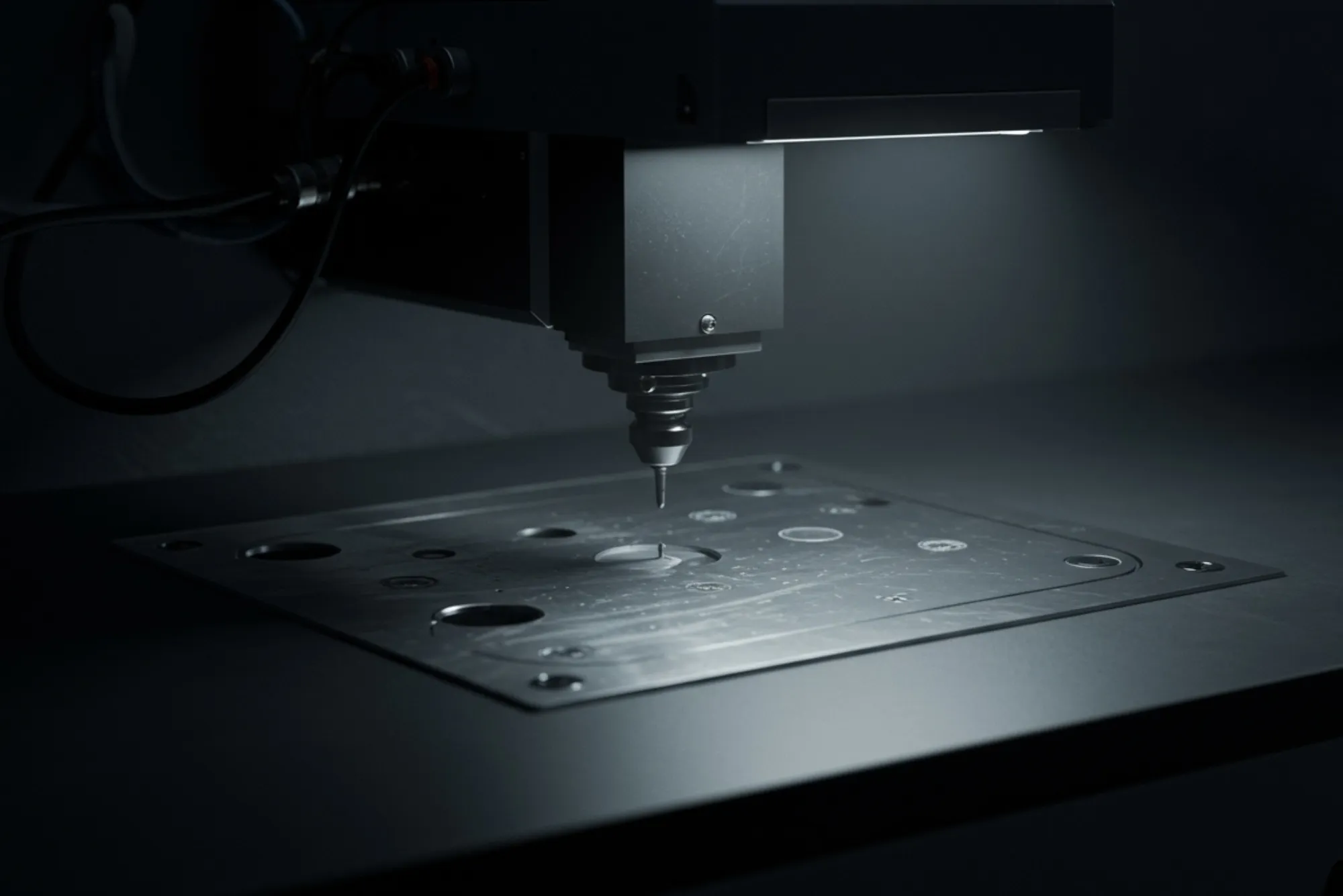

How Does Laser Marking Actually Work?

At its core, laser marking uses a concentrated laser beam that interacts with a material’s surface to alter its appearance. Depending on the type of laser, wavelength, and surface characteristics, the process can create marks through:

-

Engraving (material removal)

-

Annealing (color change through heating)

-

Surface etching (micro-level texture change)

-

Foaming and carbonizing (mostly on plastics)

The key advantage? The surface is marked without force, friction, or chemical reaction, which means no tool wear and no risk of surface deformation. Whether you’re adding a QR code on a metal tool, branding your leather products, or coding electronic components, the precision remains unmatched.

Why Industries Prefer Laser Marking Over Traditional Methods

In many industries today, traceability and compliance are no longer optional—they’re mandatory. From medical devices that require UDI (Unique Device Identification) to aerospace parts that must withstand extreme conditions, markings must survive friction, heat, and corrosion. Laser marking checks all those boxes.

Some advantages professionals value:

-

Environmental Sustainability: No ink, no chemicals, no waste.

-

Lifetime Permanence: Marks don’t fade, chip, dissolve, or peel.

-

High-Speed Accuracy: Automated systems can mark thousands of parts per hour.

-

Zero Maintenance: No refilling cartridges, no changing tips or templates.

-

Micro-Level Precision: Perfect for electronics, jewelry, and micro-text codes.

Manufacturers also appreciate the reduced long-term cost. Even though the initial machine investment can be high, the savings in consumables and downtime make laser marking more economical in the long run.

Where Is Laser Marking Used in Real-World Applications?

You’ve already interacted with laser-marked products even if you didn’t realize it.

Common examples include:

-

Serial numbers on phone chargers

-

Barcodes on automotive parts

-

Logo engravings on stainless steel bottles

-

Lot numbers on medical instruments

-

Branding on luxury watches and jewelry

-

PCB component identification in electronics

-

Traceability codes on aerospace parts

Even personalized accessories—like engraved pens, rings, or photo frames—use the same industrial-grade technology, just scaled differently.

The Connection Between Laser Marking and Laser Paint Removal

While laser marking focuses on adding permanent identification, laser paint removal works the opposite way—removing coatings, dirt, rust, or paint without damaging the base surface. The same laser precision that allows micro-engraving also allows cleaning surfaces at a molecular level.

Many factories now combine both technologies in a single workflow. For example:

-

A metal part arrives with a painted or coated surface.

-

Laser paint removal is used to clean a specific area.

-

The now-exposed metal is marked with a permanent laser code.

-

The part continues through production without rework or waste.

Industries such as automotive restoration, aviation maintenance, and heavy machinery refurbishing rely heavily on laser paint removal because it avoids sanding, chemical stripping, and abrasive blasting—all of which can weaken the original material.

So, whether you’re marking a new component or restoring an old one, lasers offer a cleaner, faster, and more controlled experience.

Common Myths About Laser Marking (And the Reality)

Some people hesitate to invest in laser marking because of common misconceptions. Let’s clear a few:

-

“Laser marking burns or damages the material.”

Not if configured correctly. Many marks barely scratch the surface and simply change the structure or color. -

“It’s too expensive for small businesses.”

Modern desktop laser markers are now available at entry-level pricing, especially for wood, acrylic, and light metals. -

“Only factories need laser marking.”

Today, it’s widely used in e-commerce (custom gifts), crafting businesses, branding agencies, and even barcode labeling for inventory systems. -

“Once marked, errors can’t be fixed.”

True—but with laser paint removal or light re-polishing, mistakes can often be corrected without replacing the entire part.

Choosing the Right Laser for Marking Different Materials

Not all lasers are equal. Fiber lasers, CO₂ lasers, UV lasers, and green lasers all behave differently. The ideal choice depends on the surface type:

-

Fiber laser: Best for metals, engineering plastics

-

CO₂ laser: Best for organic materials (wood, leather, paper)

-

UV laser: Best for sensitive plastics and glass

-

Green laser: Best for reflective or delicate materials

If you plan to mark multiple materials, hybrid systems exist—but most industries stick with a specialized laser type for consistent quality.

Practical Tips Before You Invest in Laser Marking Technology

From my experience, here are the top things to consider before buying or outsourcing laser marking:

-

Know your material type – marking a stainless steel part is not the same as marking ABS plastic.

-

Think about scale – high-volume production requires automation-ready systems.

-

Test before purchasing – always request sample markings from the machine supplier.

-

Factor in future needs – if you’ll later add traceability, barcodes, or serial automation, choose a machine with software compatibility.

-

Check after-sales support – especially if you’re new to industrial lasers.

Many suppliers also offer combined systems that can mark, cut, engrave, and remove paint—making them more versatile for manufacturing lines.

Final Thoughts: Is Laser Marking the Future of Industrial Identification?

Absolutely. As industries move toward smart manufacturing, robotics, and Industry 4.0 standards, digital traceability is becoming essential. Laser marking is reliable, sustainable, programmable, and compatible with automation—making it one of the most future-proof marking methods available.

And when paired with modern surface-processing solutions like laser paint removal, it creates a fully contactless and chemical-free workflow that aligns with global environmental and efficiency standards.

Whether you’re a factory owner, product designer, metalworker, or small craft business, now is the perfect time to explore how laser marking can upgrade your process and product value.